Why Correctly Defining Sketch Entities is Critical in 3D Modelling

When it comes to 3D modelling, your sketches are the backbone of the design. They define geometry, relationships, and constraints that drive the entire model. If these sketches are poorly defined, you risk instability, rebuild errors, and wasted time. In this post, we’ll explore why fully defining sketch entities matters, best practices, and real-world examples.

What Does “Fully Defined” Mean?

In most CAD software, a sketch is considered fully defined when:

- All entities have fixed dimensions.

- Geometric relationships (constraints) are applied.

- There are no degrees of freedom left for unintended movement.

Example:

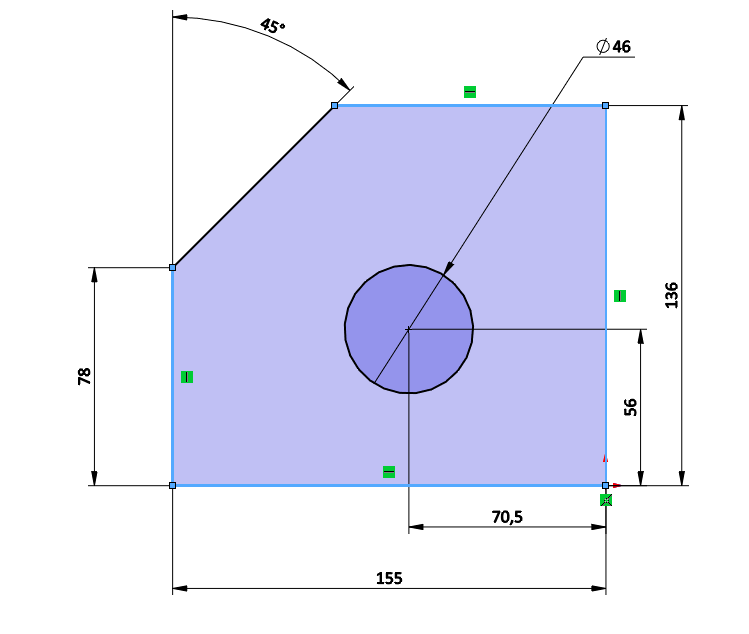

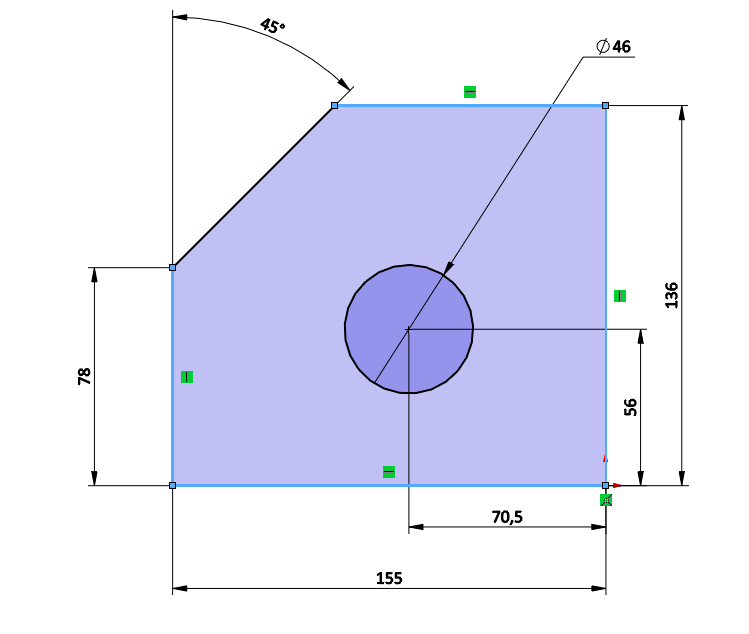

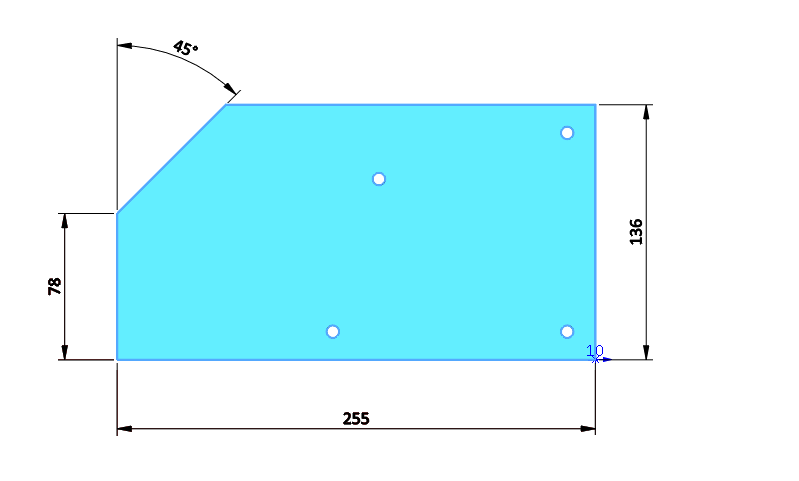

Imagine a shape intended to represent a mounting plate. If you apply no dimensions or constraints the shape is not to size and entities can move unpredictably when other features change.

Sketch unconstrained – lines may not be vertical, horizontal or perpendicular to each other. No dimensions or other constraints..

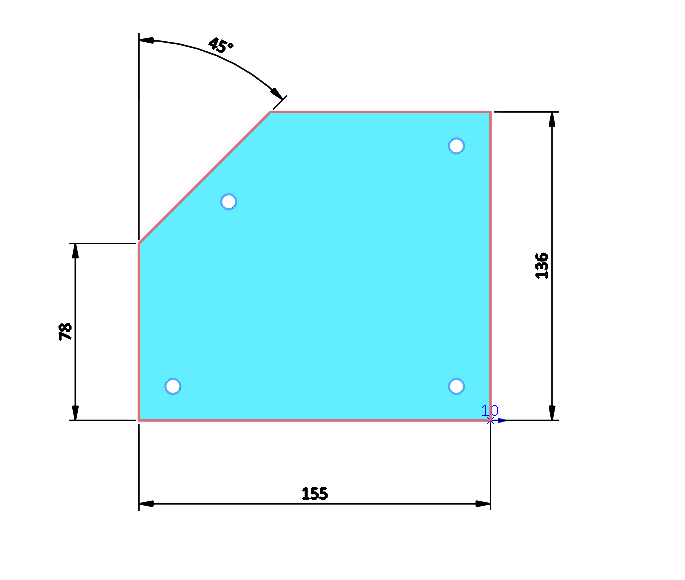

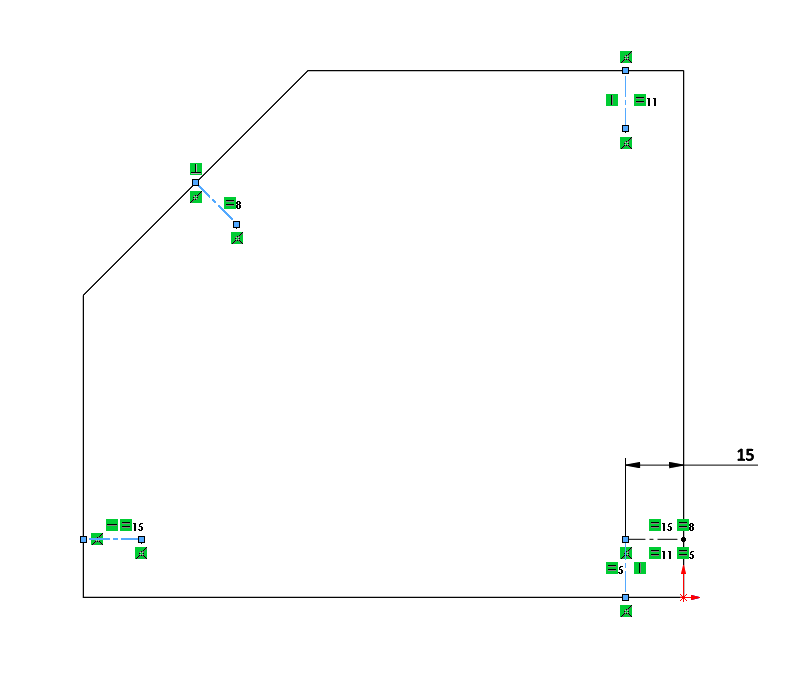

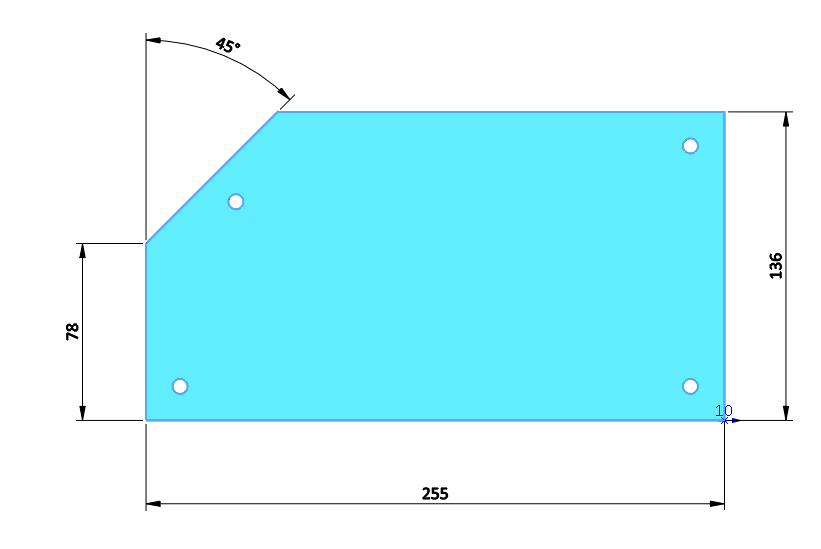

Sketch Constrained

Why It Matters

1. Predictable Behavior

Undefined sketches can shift unexpectedly during updates, causing downstream features to fail.

2. Preserves Design Intent

Constraints communicate intent—whether two holes should stay aligned or a slot should remain centered. Without them, the software guesses, and that guess is rarely correct.

3. Improved Model Stability

Fully defined sketches reduce rebuild errors and make your model robust against changes.

4. Efficiency

Fixing undefined sketches later is time-consuming. Doing it right from the start saves hours.

Best Practices for Defining Sketches

- Apply Geometric Constraints: Use horizontal, vertical, parallel, and perpendicular constraints.

- Dimension Strategically: Avoid over-dimensioning; use the minimum necessary.

- Check Sketch Status: Most CAD tools indicate whether a sketch is fully defined—make this a habit.

- Plan for Change: Anticipate which dimensions will vary and constrain accordingly.

Common Mistakes to Avoid

- Over-Dimensioning: Adding redundant dimensions can cause conflicts.

- Ignoring Relations: Relying solely on dimensions without geometric constraints.

- Leaving Construction Geometry Undefined: Even reference lines should be constrained.

Example Scenario

You’re designing a plate with multiple holes. If the hole pattern isn’t fully defined, resizing the plate will miss-align the holes, leading to manufacturing errors.

Conclusion

Fully defining sketches isn’t just a best practice—it’s essential for creating robust, parametric models. Invest time upfront, and you’ll save countless hours later while ensuring your design intent remains intact.